How to measure a sanding belt?

How to measure a sanding belt?

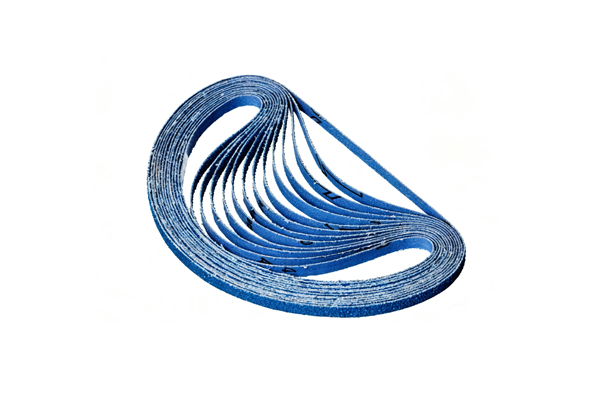

Sanding belts are essential tools for woodworking, metalworking, and industrial finishing, powering belt sanders to tackle heavy-duty material removal and surface smoothing. However, choosing the right replacement sanding belt hinges on accurate measurement—an incorrect size will not fit the sander, leading to inefficiency, equipment damage, or safety hazards. Measuring a sanding belt is a straightforward process, but it requires attention to detail and an understanding of key dimensions.

The primary dimensions of a sanding belt are length and width, which vary based on the sander’s design. Before measuring, it is critical to disconnect the sander from its power source and remove the existing belt safely. For manual measurement, start with the width, as it is the simpler dimension to determine. Use a standard tape measure or ruler to measure the distance across the flat surface of the belt, from one edge to the other. Ensure the tape is aligned parallel to the edges to avoid skewed readings—even a 1/8-inch discrepancy can render the belt unusable.

Measuring the length of a sanding belt requires a slightly different approach, as belts are circular when installed but lay flat when removed. The most accurate method is the “flat length” measurement: lay the belt flat on a clean, level surface, ensuring it is not stretched or compressed. Position the tape measure at one end of the belt’s inner circumference and extend it to the opposite end, following the natural curve of the belt’s back. For seamless belts (the most common type), this measurement reflects the true length needed for a proper fit. Avoid pulling the belt tightly while measuring, as this will stretch the material and result in an overstated length.

For worn or damaged belts that cannot be laid flat, an alternative method involves using the sander’s specifications. Most belt sanders have a label or user manual that lists the recommended sanding belt size (e.g., 4 x 24 inches for handheld models, 6 x 48 inches for benchtop units). If the label is missing, measure the sander’s drum and idler pulley to calculate the belt length. The formula for approximate length is: 2 x (distance between the centers of the drum and idler pulley) + π x (average diameter of the two pulleys). This method is less precise than direct measurement but works as a reliable backup.

Specialized tools can enhance measurement accuracy, especially for industrial or high-precision applications. Calipers are ideal for measuring narrow belts (less than 1 inch wide) where a tape measure may be cumbersome. For large-format belts used in industrial sanders, a measuring tape with a locking mechanism prevents slippage during length measurement. Additionally, digital measuring tools (such as laser distance meters) can reduce human error, though they are not necessary for most home or hobbyist projects.

Beyond length and width, other factors must be considered to ensure compatibility, even with correctly measured belts. The belt’s thickness (gauge) affects how it fits around the sander’s pulleys—thicker belts may not flex properly on small-diameter pulleys, while thinner belts risk slipping. Most sanding belts have a thickness of 0.035 to 0.050 inches, but this should align with the sander’s manufacturer recommendations. Additionally, the belt’s joint type (seamless vs. glued) can impact fit, though this is typically standardized for specific sizes.

Common mistakes to avoid during measurement include ignoring wear and tear, using damaged tools, and misinterpreting dimensions. Worn belts may shrink or stretch over time, so measuring a new replacement belt against a worn one is not reliable—always measure the sander or use the original specifications if possible. A bent ruler or stretched tape measure will produce inaccurate readings, so inspect tools before use. Finally, note that sanding belt sizes are often listed as “width x length” (e.g., 3 x 21 inches), so avoid reversing these dimensions when purchasing replacements.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China