Best type of sandpaper for wood

Best type of sandpaper for wood

The key to effective sanding lies in choosing the right sandpaper, as different types are designed to handle specific wood species, grain patterns, and project goals.

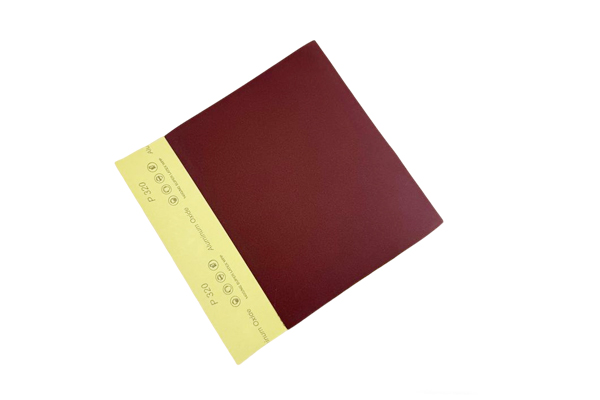

The first factor to consider is the abrasive material, which directly impacts sanding efficiency and surface finish. Aluminum oxide is the most versatile and widely used abrasive for wood. It is durable, self-sharpening, and works well on both softwoods (such as pine and cedar) and hardwoods (like oak and maple).

This material is ideal for general sanding tasks, from removing rough surfaces to fine finishing, and is available in a range of grits. For hardwoods with dense grain or stubborn imperfections, silicon carbide sandpaper is a better choice. It is harder than aluminum oxide and excels at sanding hard, smooth surfaces, including lacquered or varnished wood, making it suitable for refinishing projects where old finishes need to be stripped.

Garnet sandpaper is a natural abrasive that produces a smooth, consistent finish, making it perfect for final sanding before applying stains or paints. It is less durable than synthetic abrasives but leaves minimal scratch marks, which is crucial for achieving a professional look on visible surfaces. However, its softness means it wears down quickly on hardwoods, so it is best used for light sanding on softwoods or as a final touch-up tool.

Grit size is another essential consideration, as it determines the coarseness or fineness of the sandpaper. Grit numbers range from coarse (40–80 grit) to medium (120–180 grit) and fine (220–400 grit). Coarse grits (40–60) are used for heavy material removal, such as flattening warped wood, removing deep scratches, or shaping rough lumber. Medium grits (120–150) are ideal for smoothing surfaces after coarse sanding and preparing wood for finishing. Fine grits (220+) are used for final sanding to create a ultra-smooth surface that absorbs stains and paints evenly. For most woodworking projects, a progression from coarse to fine grit is recommended to avoid leaving deep scratches that are difficult to remove.

The backing material of sandpaper also affects its performance and application. Paper-backed sandpaper is lightweight and flexible, making it suitable for hand sanding or use on orbital sanders for flat surfaces. Cloth-backed sandpaper is more durable and tear-resistant, ideal for heavy-duty sanding with belt sanders or for sanding curved surfaces where flexibility is needed. Film-backed sandpaper is the most durable option, resistant to water and clogging, making it perfect for wet sanding— a technique used to achieve an extremely smooth finish on hardwoods or between coats of finish.

Specialized sandpapers, such as wet-dry sandpaper, are designed for specific tasks. Wet-dry sandpaper can be used with water or oil to reduce dust and prevent clogging, resulting in a finer finish. It is commonly used for sanding between coats of polyurethane or lacquer. For intricate woodwork, such as carvings or detailed furniture, foam-backed sandpaper conforms to curved surfaces and hard-to-reach areas, ensuring consistent sanding without damaging delicate details.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China