What is diamond grit sandpaper?

What is diamond grit sandpaper?

At its core, diamond grit sandpaper uses tiny synthetic diamonds as the abrasive particles instead of the usual aluminum oxide or silicon carbide. Diamonds are the hardest known natural material, so they cut through even the most stubborn surfaces with surprising efficiency. These microscopic diamonds are bonded to a backing—usually paper, film, or metal—using resins or electroplating methods that keep them firmly in place during use.

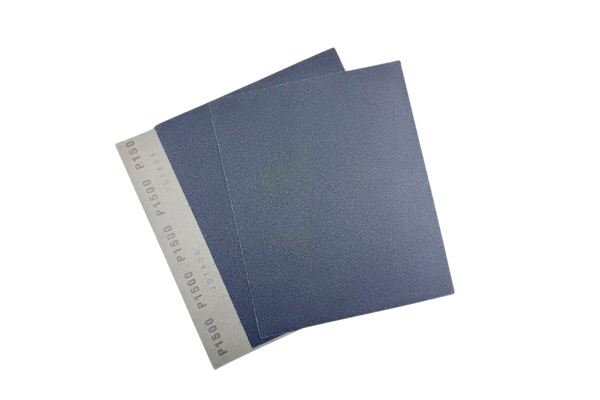

You’ll often find diamond grit sandpaper in two main forms: sheets and discs. Sheets are handy for hand-sanding small areas or detailed work, while discs attach to power tools like orbital sanders or angle grinders for larger or more aggressive tasks. The grit size varies just like traditional sandpaper—ranging from coarse (like 60 or 80 grit) for rapid material removal to ultra-fine (up to 1200 grit or higher) for polishing finishes on stone or metal.

One of the biggest advantages of diamond grit sandpaper is its durability. Because diamonds don’t dull easily, a single sheet can last significantly longer than conventional abrasives when working on hard materials. This makes it cost-effective over time, especially for professionals who regularly shape or finish concrete countertops, sharpen carbide tools, or polish gemstones.

But it’s not just about hardness—it’s also about precision. Diamond abrasives cut cleanly and consistently without loading up (clogging with debris) as quickly as other types. This is particularly useful when working with non-ferrous metals, ceramics, or composites that tend to gum up standard sandpaper. Plus, because the cutting action is so efficient, you often get a smoother finish in fewer passes.

That said, diamond grit sandpaper isn’t ideal for every job. On softer woods or plastics, it can be overkill—and expensive. Regular sandpaper works just fine there, and using diamond would be like using a sledgehammer to hang a picture. Save it for when you’re dealing with materials that laugh at normal abrasives.

Another thing to note: diamond sandpaper usually requires some form of lubrication, especially during fine finishing. Water is commonly used to keep dust down, prevent overheating, and flush away debris. Dry use is possible, but wet sanding tends to extend the life of the abrasive and improve the finish quality—particularly on stone or glass.

You’ll see diamond grit products labeled in different ways. Some manufacturers use “micron” ratings instead of grit numbers, which refer to the actual particle size in micrometers. A 120-grit diamond sheet might correspond roughly to a 125-micron size, while a 600-grit could be around 20 microns. If you’re switching between systems, it helps to check a conversion chart—but in practice, most users stick to one brand or system once they find what works.

In workshops and studios, diamond grit sandpaper has become indispensable. Jewelers use it to refine metal settings without damaging delicate stones. Stone fabricators rely on it to smooth granite edges. Even knife enthusiasts use diamond plates to sharpen high-end blades with ceramic or carbide components. Its versatility across industries speaks to its effectiveness.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China