What are velcro sandpaper discs?

What are velcro sandpaper discs?

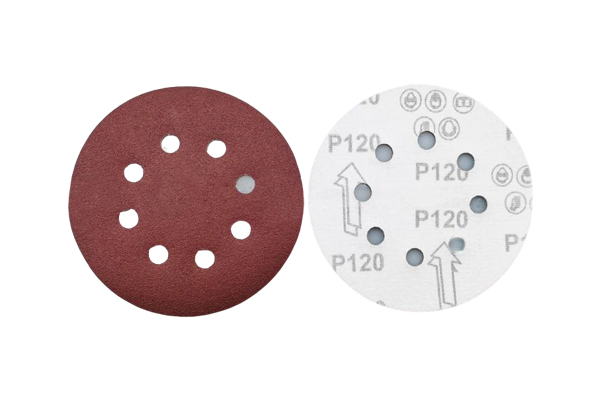

Velcro sandpaper discs get their name from the hook-and-loop fastening system (commonly branded asVelcro®, though the term is often used generically). One side of the disc features a fabric-like loop surface, while the sander’s backing pad has a matching hook surface. When pressed together, they bond securely—but can be peeled off instantly with minimal effort.

This design eliminates the need for adhesives, clamps, or complicated mounting systems. Unlike traditional PSA (pressure-sensitive adhesive) discs that stick permanently until worn out or forcibly removed—often leaving sticky residue—Velcro discs are reusable, interchangeable, and mess-free.

Key Advantages Over Traditional Sanding Discs

1. Quick Grit Changes

Sanding a project usually requires multiple grits—from coarse (e.g., 80) for material removal to fine (e.g., 220) for smoothing. With Velcro discs, switching between grits takes seconds. Just peel off the old disc and press on a new one. This saves significant time during multi-stage sanding jobs, especially in automotive or furniture restoration.

2. Reusable Backing Pad

The sander’s backing pad lasts for hundreds of disc changes. As long as the hook surface remains intact (and free of dust buildup), it will hold new discs firmly. This reduces long-term costs and waste.

3. No Residue or Damage

PSA discs often leave behind gummy adhesive when removed, which can clog the pad or affect performance. Velcro systems avoid this entirely, keeping your tool clean and functional.

4. Better Heat and Dust Management

Many Velcro sanding discs feature perforated patterns (often 6- or 8-hole designs) that align with dust extraction ports on modern sanders. This allows built-in vacuums to pull away sawdust efficiently, preventing clogging (“loading”) and overheating—both of which shorten abrasive life.

Velcro sanding discs are widely used across industries:

– Woodworking: For shaping, leveling, and finishing tabletops, cabinets, or musical instruments. The quick-change system lets woodworkers fine-tune surfaces without interrupting workflow.

– Auto Body Repair: Technicians use them for feathering edges, smoothing body filler, and prepping paint surfaces. The ability to switch grits rapidly is crucial when working on curved panels or tight corners.

– Metal Fabrication: From deburring stainless steel to polishing aluminum, Velcro discs paired with appropriate abrasives (like zirconia or ceramic) deliver consistent results.

– DIY Home Projects: Whether refinishing floors, sanding drywall, or restoring vintage furniture, hobbyists appreciate the ease and cleanliness of the system.

Types of Abrasives Used

Velcro discs come with various abrasive materials bonded to a flexible backing (usually polyester or fiber):

– Aluminum Oxide: General-purpose, good for wood and metal.

– Silicon Carbide: Sharper and harder, ideal for wet sanding or finishing paints.

– Ceramic Alumina: Extremely durable and self-sharpening, used in heavy-duty material removal.

– Zirconia Alumina: Tough and heat-resistant, common in metalworking.

The choice depends on the material being sanded and the desired finish.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China