Can you polish quartz with sandpaper?

Can you polish quartz with sandpaper?

Can you polish quartz with sandpaper? Yes, you can polish quartz with sandpaper, but the process requires precision, the right grit sequence, and care to avoid damaging the stone.

1. Gather the Right Supplies

Quartz’s hardness demands durable sandpaper and supporting tools. Skip low-quality paper, as it will wear down quickly and scratch the surface. Here’s what you need:

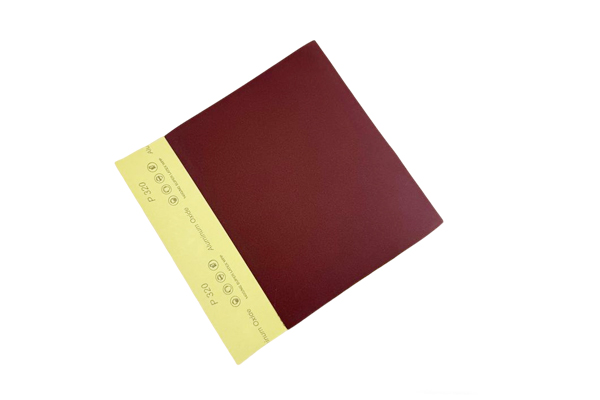

– Sandpaper: Wet/dry silicon carbide sandpaper (the only type tough enough for quartz). Avoid aluminum oxide paper—it’s too soft.

– Grit sequence: Start with medium grit (240–400) for smoothing, progress to fine (600–800), then very fine (1000–2000), and finish with ultra-fine (3000–5000) for gloss.

– Water source: A spray bottle or bucket—wet sanding is mandatory to reduce heat, prevent scratches, and prolong sandpaper life.

– Sanding block/pad: A rigid foam or rubber block ensures even pressure; avoid sanding by hand, which causes uneven surfaces.

– Clean cloths: Lint-free microfiber cloths to wipe away sludge and check progress.

– Quartz polish (optional): A dedicated quartz polishing compound to enhance shine after sanding.

2. Prepare the Quartz Surface

Start by cleaning the quartz thoroughly with mild soap and water to remove dust, grease, or debris. Dry it completely—any particles left on the surface will scratch it during sanding.

If the quartz has deep scratches, chips, or stains, address them first. For small chips, use a quartz repair kit before polishing. For deep scratches (deeper than 1mm), begin with 240-grit sandpaper to level the area—coarser grits (like 120) can create irreversible scratches on quartz, so avoid them unless absolutely necessary.

3. Wet Sanding Step-by-Step

Wet sanding is non-negotiable for quartz: it cools the surface (preventing thermal damage), flushes away sludge, and creates a smoother finish. Follow this grit progression:

– Medium grit (240–400): Saturate the sandpaper and quartz surface with water. Attach the paper to the sanding block and sand in a consistent, circular motion (or along the stone’s natural grain, for quartzite). Apply light, even pressure—let the sandpaper do the work. Keep the surface wet at all times, re-spraying every 30 seconds. Sand until all deep scratches or uneven areas are smoothed. Wipe away sludge with a damp cloth to check progress.

– Fine grit (600–800): Switch to 600-grit sandpaper, repeating the wet sanding process. This step removes scratches left by the medium grit. Move to 800-grit next, sanding until the surface feels uniformly smooth to the touch.

– Very fine grit (1000–2000): Progress to 1000-grit, then 2000-grit. At this stage, the surface will start to develop a subtle sheen. Sand in overlapping circular motions, ensuring no area is missed. Rinse the surface frequently to remove residue.

– Ultra-fine grit (3000–5000): Finish with 3000 or 5000-grit sandpaper. This step refines the surface to a near-gloss finish. Sand gently, keeping the paper and surface wet, until the quartz reflects light evenly.

4. Final Polishing

For a salon-worthy gloss, follow sanding with a quartz polishing compound. Apply a small amount of compound to the surface and buff it with a clean microfiber cloth or a buffer pad (low speed). Buff in circular motions until the compound dries to a haze, then wipe it away with a dry cloth. This step enhances the shine and seals minor imperfections.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China