What is the longest-lasting sanding disc?

What is the longest-lasting sanding disc?

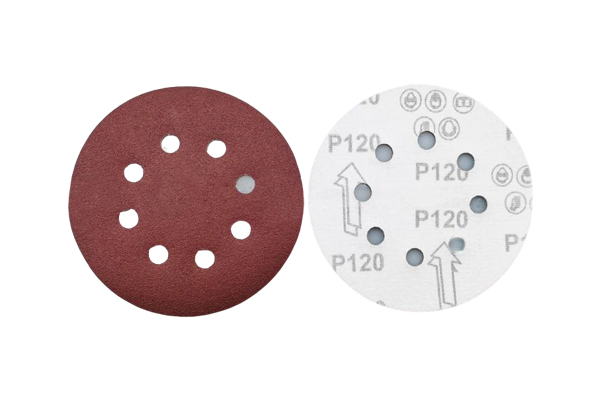

A long-lasting sanding disc not only reduces the frequency of disc replacement but also minimizes downtime, lowers material costs, and ensures consistent sanding quality. But what exactly makes a sanding disc last longer than others, and which type deserves the title of the longest-lasting?

First and foremost, the abrasive material is the primary determinant of a sanding disc’s lifespan. Abrasive grains are the “teeth” of the disc, and their hardness, wear resistance, and ability to retain sharpness directly impact how long the disc can perform effectively. Common abrasive materials include aluminum oxide, silicon carbide, zirconia alumina, and ceramic alumina. Among these, ceramic alumina stands out as the most durable option for most applications. Ceramic alumina grains are engineered to be extremely hard—harder than aluminum oxide and silicon carbide—and they possess a unique self-sharpening property. As the grains wear down during sanding, they fracture along sharp edges, exposing new cutting surfaces.

Zirconia alumina is another high-durability abrasive material, often used in metalworking applications. It is slightly less hard than ceramic alumina but offers excellent toughness, making it resistant to chipping and fracturing when sanding hard or brittle metals. Zirconia alumina also exhibits some self-sharpening characteristics, though not as pronounced as ceramic alumina. In contrast, aluminum oxide, the most common abrasive material, is affordable but less durable, making it suitable for light-duty sanding tasks. Silicon carbide, while hard, is brittle and tends to wear out quickly when used on tough materials, limiting its lifespan.

Beyond the abrasive material, the bonding agent that holds the abrasive grains to the disc’s backing plate is another critical factor. The bonding agent must be strong enough to keep the grains attached during high-speed sanding, resist heat buildup, and withstand the mechanical stress of the sanding process. Resin bonds are the most widely used in modern sanding discs, with phenolic resin being the preferred choice for durable discs. Phenolic resin is heat-resistant, chemical-resistant, and offers exceptional bond strength, ensuring that the abrasive grains stay firmly attached even during prolonged, high-pressure sanding. In contrast, weaker bonds like animal glue or acrylic resin can break down quickly under heat and stress, causing grains to脱落 (fall off) prematurely and shortening the disc’s lifespan.

The backing material of the sanding disc also plays a role in its durability. The backing must be rigid enough to support the abrasive grains and maintain the disc’s shape, yet flexible enough to conform to curved or irregular surfaces. Common backing materials include paper, cloth, and film. Paper backing is lightweight and affordable but prone to tearing, especially when used with water or in heavy-duty applications. Cloth backing, typically made from cotton or polyester, is more durable and tear-resistant, making it suitable for heavy-duty sanding. Film backing, usually made from polyester, is the most durable option—it is water-resistant, tear-resistant, and can withstand high temperatures and pressures. Sanding discs with film backing are often used in wet sanding applications and for sanding hard materials, as they maintain their integrity longer than paper or cloth-backed discs.

When considering all these factors, the longest-lasting sanding discs on the market are typically those featuring ceramic alumina abrasive grains, a phenolic resin bond, and a film or heavy-duty cloth backing. One such example is the 3M Cubitron II sanding disc, which uses precision-shaped ceramic alumina grains and a strong phenolic resin bond. The precision shaping of the grains enhances their self-sharpening ability, while the phenolic resin ensures that the grains remain attached even during aggressive sanding.

Another notable option is the Norton Quantum Ceramic sanding disc, which also utilizes ceramic alumina grains and a heat-resistant phenolic bond. Designed for heavy-duty sanding of metal, wood, and composite materials, these discs offer excellent durability and consistent performance. The Norton Quantum Ceramic discs are particularly popular in automotive and aerospace industries, where long-lasting sanding tools are essential for maintaining productivity.

It is important to note that the lifespan of a sanding disc also depends on the application and usage conditions. Even the most durable disc will wear out quickly if used on an extremely hard material at excessive speed or pressure. Proper usage—such as matching the disc to the material, using the correct sanding speed, and avoiding excessive pressure—can significantly extend the disc’s lifespan. Additionally, wet sanding can reduce heat buildup and prolong the life of the disc, as water cools the abrasive grains and prevents them from overheating and wearing out prematurely.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China