Introduction to the correct storage methods for abrasive belts

Introduction to the correct storage methods for abrasive belts

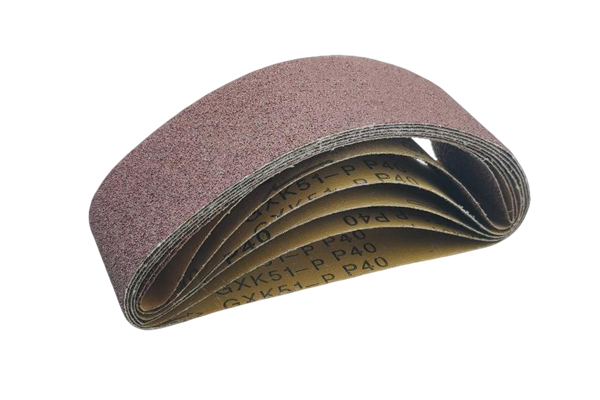

Abrasive belts are critical consumables in metalworking, woodworking, and industrial finishing, valued for their efficiency in grinding, sanding, and polishing. However, improper storage can compromise their structural integrity, abrasive performance, and service life—leading to premature wear, reduced cutting power, or even complete failure during use. To maintain the quality and functionality of abrasive belts, adherence to standardized storage practices is essential.

Core Environmental Requirements

The storage environment is the primary factor affecting abrasive belt condition. Key parameters to control include temperature, humidity, and air quality.

– Temperature Control: Store abrasive belts in a temperature-stable environment, ideally between 15°C and 25°C (59°F and 77°F). Extreme heat (above 30°C/86°F) can soften the adhesive bonding the abrasive grains to the backing, causing grains to dislodge or the belt to warp. Extreme cold (below 10°C/50°F) can make the backing material brittle, increasing the risk of cracking during installation or use.

– Humidity Management: Relative humidity (RH) should be maintained between 40% and 60%. High humidity (above 65%) can lead to moisture absorption, which damages paper or cloth backings, promotes rust on metal abrasive grains (e.g., aluminum oxide), and weakens adhesive bonds. Low humidity (below 35%) can cause the backing to dry out and shrink, altering the belt’s dimensions and leading to misalignment during operation.

– Air Quality: Keep storage areas clean, dry, and free of dust, oil, and chemical fumes. Dust and debris can accumulate on abrasive surfaces, reducing cutting efficiency. Oil or chemical vapors can contaminate the adhesive and backing, leading to premature degradation. Avoid storing abrasive belts near heavy machinery, chemical storage tanks, or areas with frequent oil leaks.

Physical Handling and Placement

Improper physical storage can cause permanent deformation or damage to abrasive belts, especially for flexible cloth or paper-backed varieties.

– Avoid Folding or Creasing: Never fold abrasive belts, as creases can crack the backing or break abrasive grains. For belts with a diameter larger than 30 cm (12 inches), store them horizontally on cylindrical racks or spools to maintain their original circular shape. For smaller belts, use flat, rigid shelves to prevent bending.

– Prevent Compression: Do not stack heavy objects on top of abrasive belts. Excessive pressure can compress the backing, distort the belt’s structure, and cause uneven wear during use. When stacking belts on shelves, limit the stack height to 10–15 belts per layer to avoid compression.

– Separate by Type and Grit: Store different types of abrasive belts (e.g., aluminum oxide, silicon carbide) and grit sizes separately. This prevents cross-contamination and ensures easy access. Label each storage container or rack with the belt type, grit size, and manufacturing date to track shelf life and avoid using expired products.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China