Xuchang JinKaiYan abrasives:What sandpaper is best for metals?

Xuchang JinKaiYan abrasives:What sandpaper is best for metals?

Not all sandpapers are suitable for metals; the right choice prevents scratching, removes rust or corrosion effectively, and prepares surfaces for painting, welding, or polishing.

Abrasive Materials:

The most effective abrasive materials for metal are aluminum oxide, silicon carbide, and ceramic aluminum oxide. Each has distinct advantages for different metalworking tasks.

– Aluminum Oxide: The most common and versatile option for general metal sanding. It is durable, self-sharpening (abrasive grains break down to expose new sharp edges), and works well on steel, iron, and stainless steel. It is ideal for removing rust, deburring, and preparing surfaces for further finishing.

– Silicon Carbide: A harder, sharper abrasive than aluminum oxide, best for non-ferrous metals like aluminum, copper, brass, and titanium. It excels at wet sanding (to prevent dust and clogging) and produces a finer finish, making it suitable for polishing soft metals without leaving deep scratches.

– Ceramic Aluminum Oxide: A premium choice for heavy-duty metal sanding. It is more durable than standard aluminum oxide, retains its sharpness longer, and is ideal for grinding down welds, removing thick rust, or sanding hard metals like tool steel. It is often used in industrial settings for high-volume projects.

Avoid sandpapers with garnet abrasives for metal—garnet is soft and dulls quickly on hard metal surfaces, making it inefficient and prone to clogging.

Grit Size: Matching Coarseness to Task

Grit size determines the aggressiveness of the sandpaper. For metals, grit sizes range from coarse (40–60) to ultra-fine (1000–2000), with each range serving a specific purpose:

– Coarse Grit (40–80): Used for heavy material removal, such as stripping thick rust, removing paint from metal, or shaping rough edges. It leaves deep scratches, so it is only suitable for the initial stages of sanding.

– Medium Grit (100–180): Ideal for smoothing surfaces after coarse sanding, removing minor rust, or preparing metal for priming. It balances material removal and finish quality for most general metal projects.

– Fine Grit (220–400): Used for final smoothing before painting or welding. It removes scratches from medium grit and creates a uniform surface that adheres well to coatings.

– Ultra-Fine Grit (600–2000): Reserved for polishing metal surfaces to a mirror-like finish. Often used with wet sanding (especially for non-ferrous metals) to minimize dust and achieve a smooth, scratch-free result.

For best results, progress from coarse to fine grits, ensuring each grit removes the scratches left by the previous one.

Backing Type: Durability for Metal Applications

The backing of sandpaper affects its durability and usability, especially for metal sanding, which can be abrasive and generate heat.

– Paper Backing: Lightweight and affordable, but less durable. Suitable for light sanding tasks (e.g., fine polishing) but not recommended for heavy-duty metal work, as it can tear or wear out quickly.

– Cloth Backing: More durable and flexible than paper, making it ideal for sanding curved metal surfaces or heavy-duty tasks. Cloth-backed sandpaper resists tearing and heat, making it suitable for power sanders (e.g., orbital sanders) used on metal.

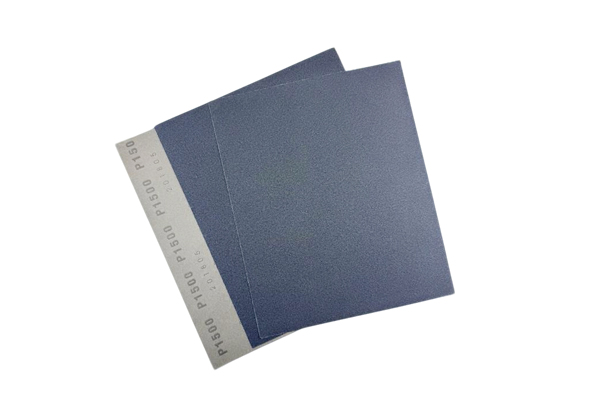

– Film Backing: A premium option for wet sanding. It is waterproof, tear-resistant, and prevents clogging, making it perfect for ultra-fine polishing of non-ferrous metals like aluminum or brass.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China