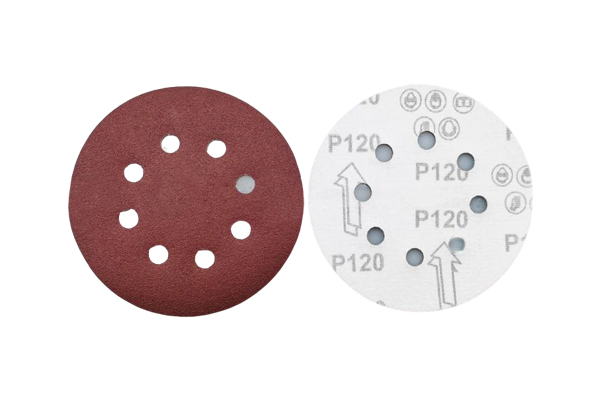

Xuchang JinKaiYan abrasives:What are the holes in sanding discs for?

Xuchang JinKaiYan abrasives:What are the holes in sanding discs for?

The world of sanding is a realm where precision meets craftsmanship, and every detail plays a crucial role in achieving optimal results.

1. Heat Dissipation:

One of the primary purposes of the holes in sanding discs is to address the issue of heat generated during the sanding process. As the abrasive material of the disc interacts with the workpiece, friction is generated, leading to heat buildup. The holes in the sanding disc act as ventilation channels, allowing air to flow and dissipate heat effectively. This helps in preventing the sanding disc from overheating, which can lead to premature wear, reduced efficiency, and potential damage to both the disc and the workpiece.

2. Reduced Clogging:

Sanding is a process that involves the removal of material, and as this material is absorbed, it can accumulate on the surface of the sanding disc. The presence of holes serves a vital role in preventing clogging. As material particles are generated, the holes provide pathways for the debris to be evacuated from the sanding surface. This feature is particularly beneficial when working with softer materials or finishes prone to loading, ensuring that the sanding disc maintains optimal cutting performance throughout the task.

3. Dust Extraction:

In addition to preventing clogging, the holes in sanding discs facilitate efficient dust extraction. Dust and debris generated during the sanding process can compromise visibility, create a messy work environment, and even pose health risks. The holes act as entry points for dust extraction systems, such as vacuum attachments, allowing for the removal of particles at the source. This not only enhances the clarity of the work area but also contributes to a healthier and safer working environment.

4. Improved Sanding Precision:

The arrangement and pattern of the holes in sanding discs are designed with precision in mind. Depending on the manufacturer and the intended use of the sanding disc, the distribution and size of the holes may vary. This meticulous design contributes to improved precision during the sanding process. The holes create a balance between material removal and control, allowing craftsmen to achieve the desired finish with accuracy and finesse.

5. Extended Disc Life:

The incorporation of holes in sanding discs plays a role in extending the overall life of the disc. By promoting effective heat dissipation, reducing clogging, and facilitating dust extraction, the holes contribute to maintaining the integrity of the abrasive material and the backing of the disc. This, in turn, translates to longer-lasting performance, cost-effectiveness, and a consistent level of quality throughout the life of the sanding disc.

6. Versatility in Applications:

The versatility of sanding discs is enhanced by the presence of holes, making them suitable for a wide range of applications. Whether used in woodworking, metalworking, automotive refinishing, or other tasks, the holes contribute to adaptability and efficiency across diverse materials and finishes.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China