JinKaiYan abrasives:what grit sandpaper for alloy wheels?

JinKaiYan abrasives:what grit sandpaper for alloy wheels?

Alloy wheels are a sleek and durable addition to any vehicle, enhancing both aesthetics and performance. However, over time, they can fall victim to scratches, curb rash, oxidation, and general wear and tear. Restoring alloy wheels to their former glory often starts with sanding—a critical step that relies heavily on selecting the correct grit sandpaper.

The wrong grit can lead to uneven surfaces, deeper damage, or a finish that fails to hold paint or polish. In this guide, we’ll break down everything you need to know about choosing grit sandpaper for alloy wheels, from understanding grit ratings to matching the right grit to your specific repair task, along with practical tips to ensure a professional-quality result.

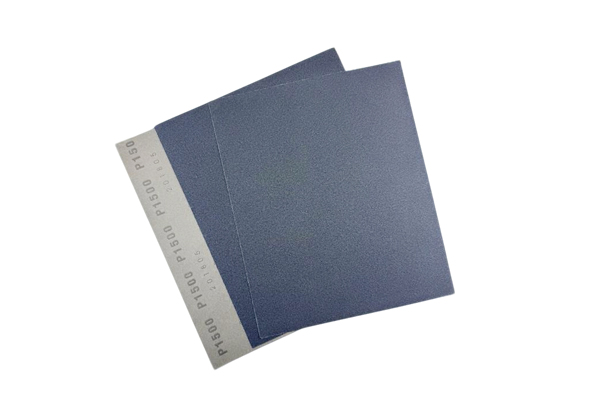

First, it’s essential to understand how sandpaper grit works. Grit refers to the number of abrasive particles per square inch of the sandpaper. Higher grit numbers mean smaller, finer particles, resulting in a smoother finish. Conversely, lower grit numbers indicate larger, coarser particles that remove material more aggressively.

For alloy wheel restoration, you’ll typically work through a range of grits—starting with a coarse grit to address major damage, then progressing to medium and fine grits to refine the surface, and finally using ultra-fine grits for a polished finish.

News

Contact Us

Contact: JinKaiYan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province China